Manufacturing has transformed significantly over the years, evolving from manual labor and mass production to automation and smart manufacturing. Innovations like Industrial IoT (IIoT), Big Data Analytics, and Manufacturing Intelligence (MI) now enable real-time monitoring and decision-making, improving efficiency and reducing waste.

What is MES?

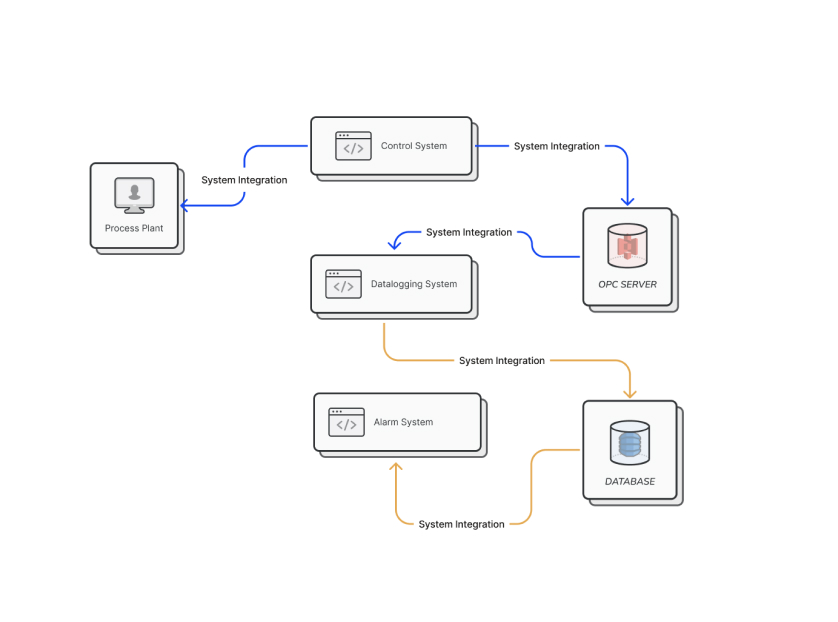

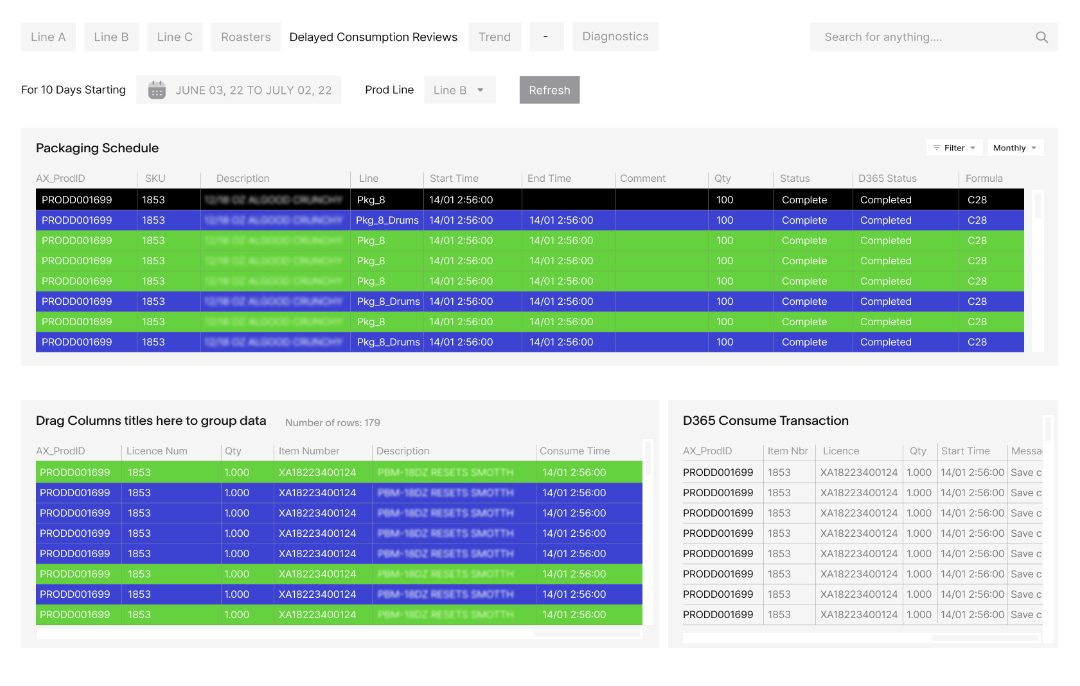

A Manufacturing Execution System (MES) is a computerized system that monitors and manages production processes on the shop floor. It integrates with ERP, PLM, and SCM systems, capturing real-time data from machines, sensors, and workers to optimize manufacturing operations. MES includes key modules such as:

Production Scheduling & Planning – Efficient resource allocation

Workforce Management – Employee productivity tracking

Quality Management – Real-time defect detection

Inventory Management – Optimized stock control

Equipment Maintenance – Preventive maintenance to reduce downtime

Why Does Your Business Need MES?

Implementing MES can boost productivity, enhance efficiency, improve quality, and aid regulatory compliance. With real-time monitoring, manufacturers can reduce costs, optimize workflows, and make data-driven decisions to remain competitive.

Value of MES for Your Business

For manufacturers, MES offers:

Improved productivity – Reduces bottlenecks & downtime

Increased efficiency – Automates processes, minimizes waste

Enhanced quality – Ensures compliance & reduces errors

Better decision-making – Provides real-time insights

Regulatory compliance – Tracks key production parameters

Cost savings – Optimizes resource utilization & lowers production costs

How INS3 Can Help

INS3 specializes in Industry 4.0 solutions, including MES, SCADA, and Industrial Data Analytics. We provide customized real-time monitoring and control solutions to enhance efficiency and reduce operational costs.

Want to optimize your manufacturing process? Contact INS3 today!